In today’s energy-conscious industrial world, efficiency and sustainability are more important than ever. Among the technologies driving this transformation, the Thermocompressor stands out as a proven solution for optimizing steam systems and reducing energy losses. Croll Reynolds, a global leader in vacuum and heat recovery systems, has perfected this concept through its innovative Multi-Nozzle Thermocompressor, designed to reclaim and reuse low-pressure steam efficiently. This article explores the inner workings of this technology, its design features, advantages, and how it serves a wide range of process industries.

Understanding the Concept of Steam Compression

In many industrial processes, steam is used as a source of heat and energy. After performing its task, this steam often becomes low in pressure and temperature, rendering it less useful and typically vented or condensed. A thermocompression system solves this inefficiency by using high-pressure motive steam to entrain and compress the low-pressure steam back to a usable pressure level. The result is a continuous cycle that reduces waste and improves the overall thermal efficiency of the plant.

Engineering Design of the Multi-Nozzle System

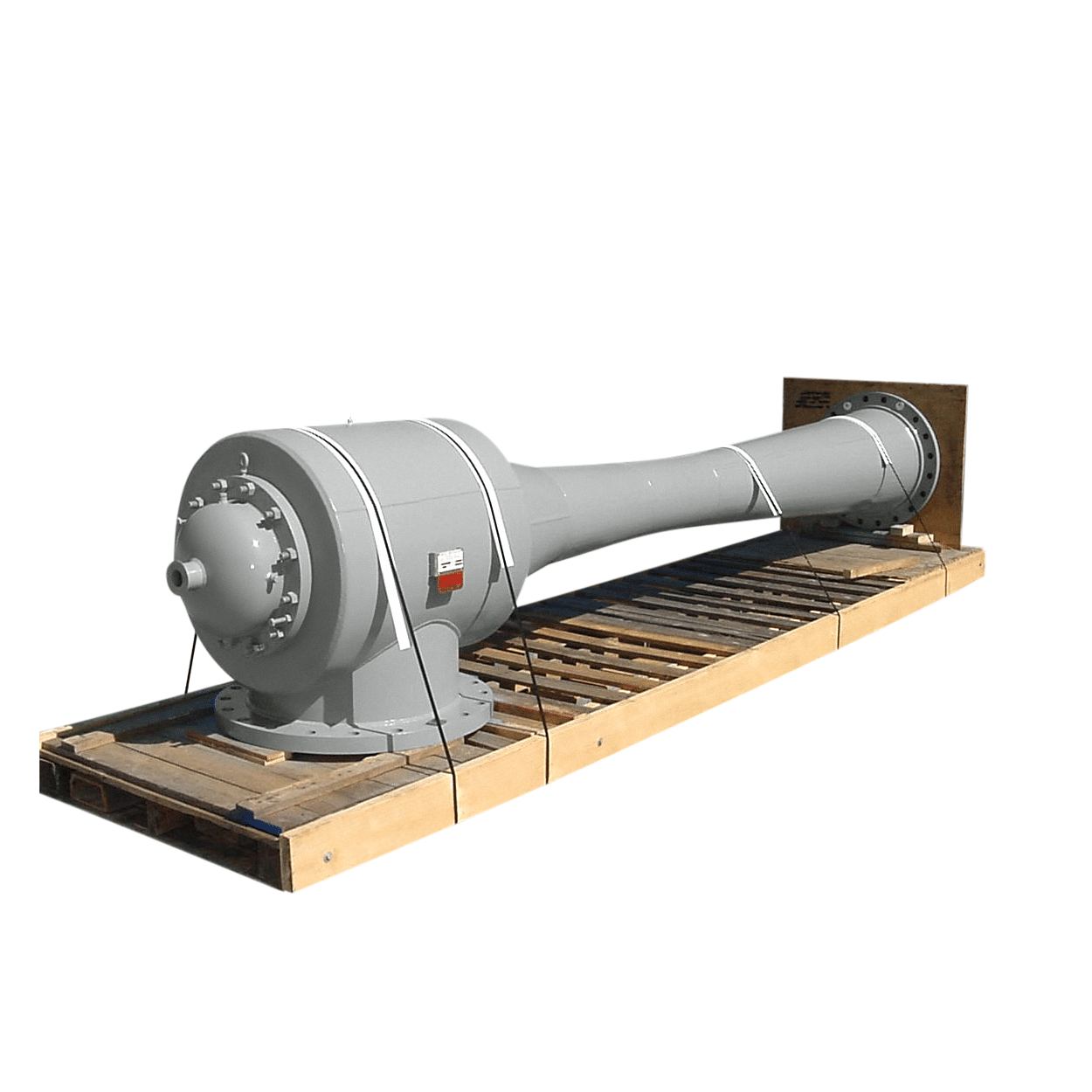

The Croll Reynolds multi-nozzle design is the heart of the system’s performance. At its core, the thermocompressor consists of three main sections — the steam chest, nozzles, and diffuser. High-pressure motive steam enters the steam chest and accelerates through specially designed nozzles, creating a region of low pressure that draws in the secondary (low-pressure) steam. Once entrained, both streams mix in the throat section and then pass through the diffuser, where velocity energy is converted into pressure. The result is a stable, high-pressure discharge flow that can be reused in various heating, drying, or evaporating applications.

Unlike mechanical compressors, the multi-nozzle thermocompressor has no rotating or moving parts, making it inherently reliable and easy to maintain. The use of multiple nozzles allows for optimized steam distribution and better control over performance, even under varying load conditions.

Construction and Material Options

Durability is a defining characteristic of the Croll Reynolds system. The thermocompressor can be fabricated from a wide range of materials including carbon steel, stainless steel, and special alloys depending on process requirements. This flexibility ensures resistance to corrosion, erosion, and thermal stress in high-temperature and high-pressure applications. For facilities handling corrosive vapors or aggressive process fluids, Croll Reynolds also offers composite and high-alloy constructions. These options extend service life and reduce maintenance intervals, ensuring reliable long-term operation.

Operational Advantages

The Croll Reynolds Multi-Nozzle Thermocompressor offers numerous operational benefits that contribute directly to lower costs and improved sustainability. First, it requires no electrical power—it operates entirely on motive steam pressure. This not only simplifies installation but also reduces dependency on auxiliary power systems.

Because it has no mechanical moving parts, wear and tear are minimal, leading to extremely low maintenance needs. The absence of lubrication systems eliminates contamination risks, an important advantage for industries such as food and pharmaceuticals.

Additionally, the thermocompressor achieves high reliability and consistent output, even when handling large volumes of vapor. Its straightforward design makes it easy to retrofit into existing systems, enabling plants to recover wasted energy without major process changes.

Energy Efficiency and Cost Savings

Energy recovery is at the core of thermocompressor technology. By recycling low-pressure steam, plants can significantly cut down on fuel consumption in boilers, as less fresh steam needs to be generated. This translates directly into lower operational costs and reduced carbon emissions. Furthermore, the Croll Reynolds multi-nozzle configuration improves motive steam efficiency by optimizing nozzle geometry and mixing dynamics. This ensures maximum entrainment ratios with minimal energy input, delivering measurable improvements in overall plant performance.

Applications Across Industries

The versatility of the thermocompressor makes it an essential component across a wide range of industries. In the chemical and petrochemical sectors, it’s used for distillation, evaporation, and vapor recovery processes. The pulp and paper industry utilizes it for black liquor concentration and paper drying, while food and beverage producers rely on it for concentration, pasteurization, and evaporation duties.

In power generation, thermocompressors help recover waste steam from turbines or condensers, maintaining vacuum levels and improving plant efficiency. They are also applied in desalination and wastewater treatment, where steam-driven evaporation is a key operation.

Ease of Integration and Upgrades

Croll Reynolds designs its thermocompressors for easy integration into both new and existing steam systems. Whether installed as part of a multi-stage vacuum system or a standalone steam recovery loop, the equipment requires minimal space and piping modifications. For operations needing flexible performance, adjustable nozzle or spindle designs are available. These allow operators to vary the motive steam flow and achieve turndown capabilities, accommodating changing process conditions without compromising efficiency.

Conclusion

The Thermocompressor remains one of the most effective tools for energy recovery in modern industrial plants, offering a perfect balance of simplicity, reliability, and performance. With decades of engineering expertise, Croll Reynolds continues to set the standard in steam compression technology through its advanced Multi-Nozzle Thermocompressor design. By transforming low-pressure steam into a reusable resource, industries can achieve substantial energy savings, lower emissions, and improved process sustainability—all while ensuring dependable, long-term operation.